Advanced Engineering

Maximum Performance

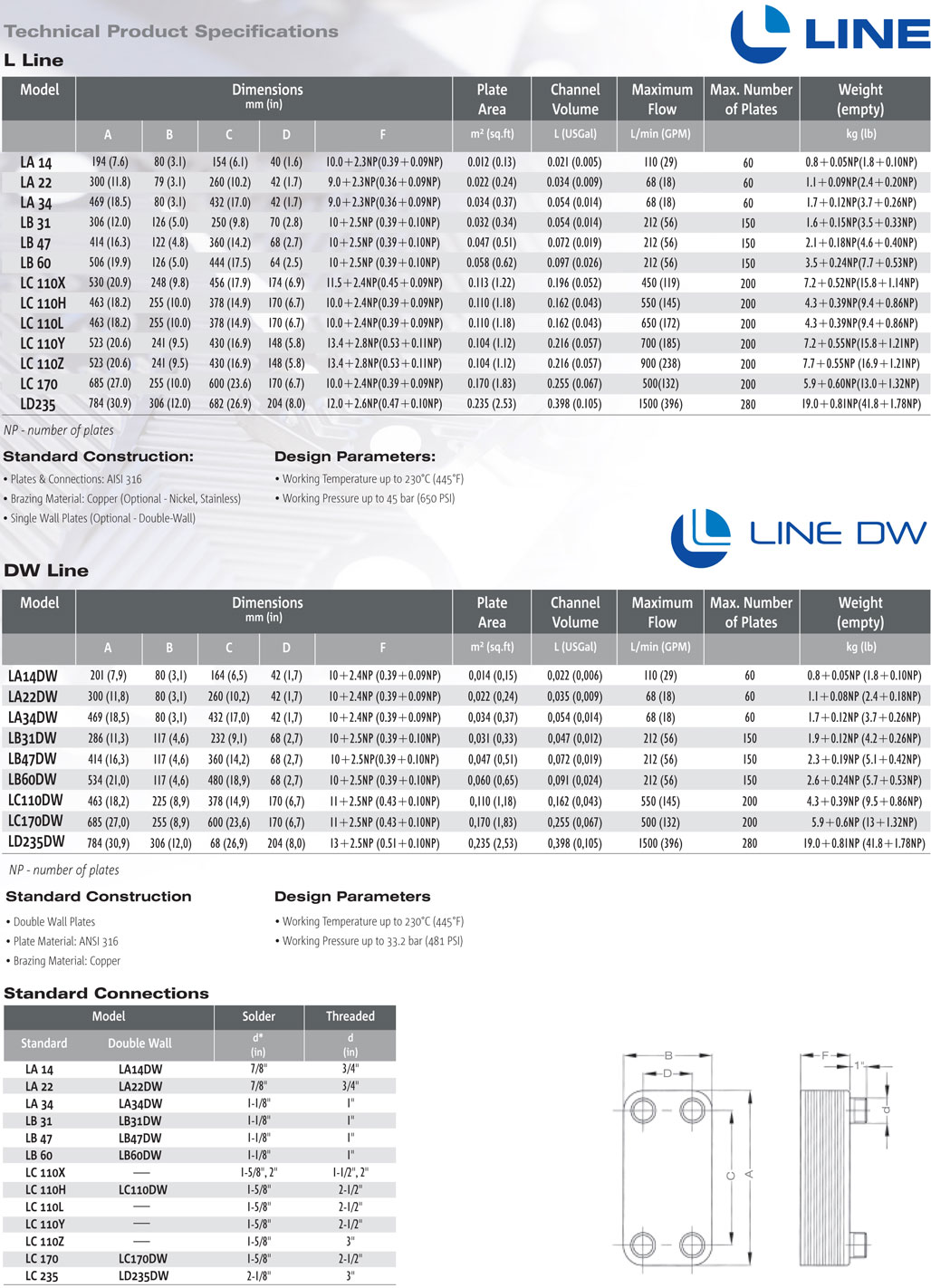

AIC L-Line Single & Double Wall Heat Exchangers

AIC L-Line Single & Double Wall Heat Exchangers

AIC Brazed Plate Heat Exchangers are available in Single-Wall, Double-Wall, and Multiple-Pass models

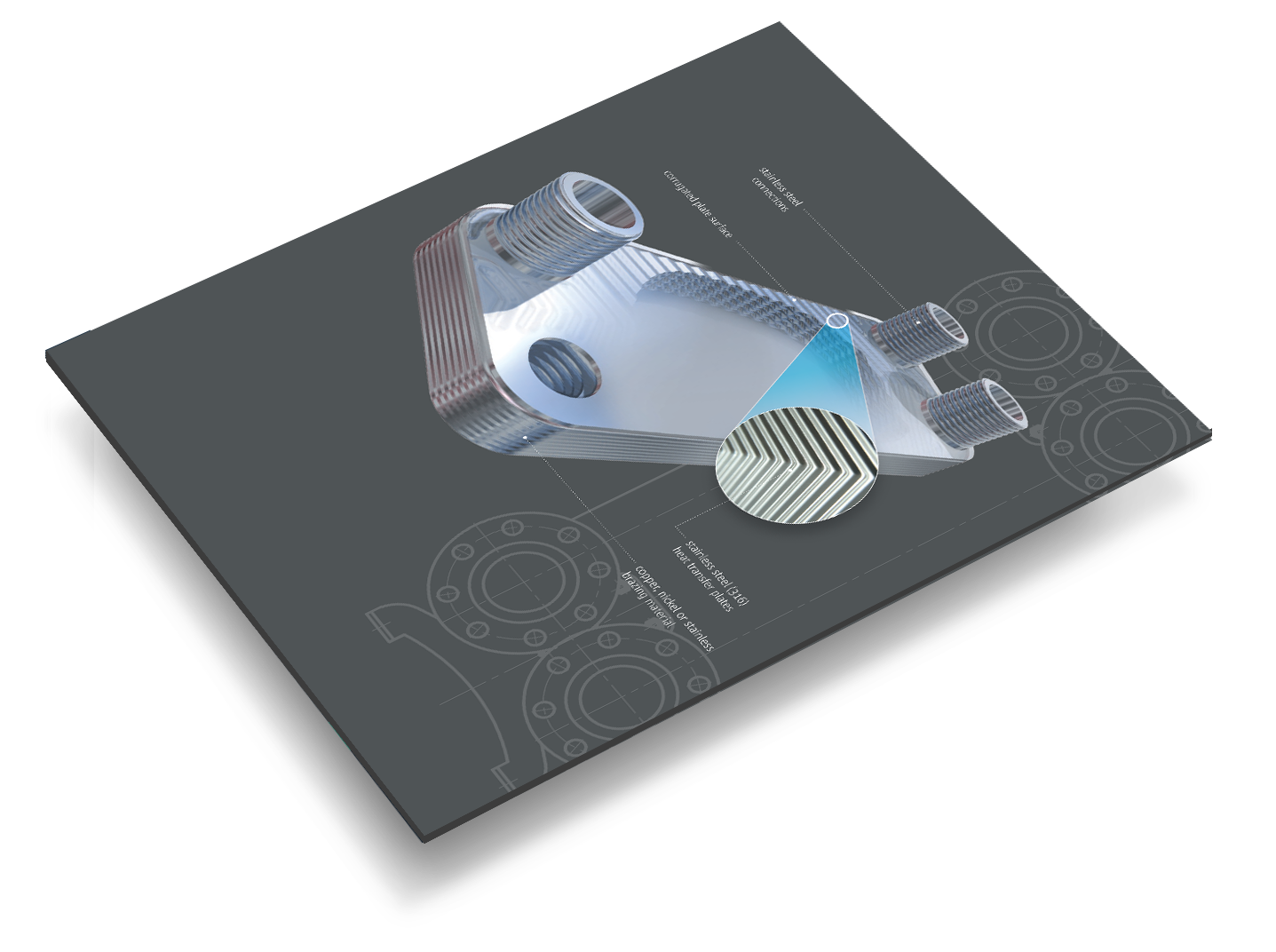

Brazed plate heat exchangers consist of stainless steel plate packs, which have embossed chevron patterns.

Special corrugation patterns promotes high turbulence flow. Turbulence dramatically improves heat transfer rates and reduces the amount of deposits inside the unit.

Corrugated plates are turned 180° to each other, causing the plate ridges to intersect, and creating a lattice of intersecting channels. The fluid can flows counter-current or co-current

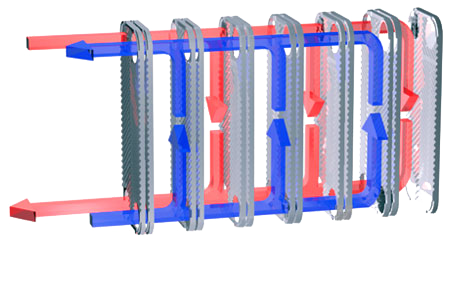

Brazed Plate Heat Exchangers come with single wall or double wall plates. Double Wall construction prevents cross contamination of fluid streams if there is an internal leak within the unit.

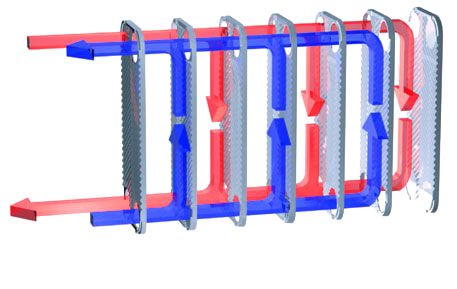

Single-pass channels are in parallel.

Brazed plate heat exchangers consist of stainless steel plate packs, which have embossed chevron patterns. The plates are turned 180° to each other, causing the plate ridges to intersect, and creating a lattice of intersecting channels. The fluids can flow in counter-current or co-current way. Special corrugation patterns promotes high turbulence flow. Turbulence dramatically improves heat transfer rates and reduces the amount of deposits inside the unit.

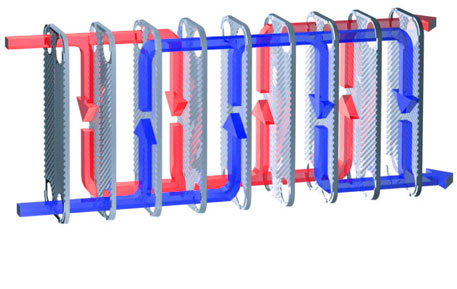

Multi-pass channels are divided in groups that are internally connected in series.

Brazed plate heat exchangers with multi-pass configuration have a number brazed plates grouped together. Groups are then connected in series to each other forming a longer flow-path for fluids. This configutation of plates increases the heat transfer capacity for the same heat exchanger footprint. Pressure drop is also increased in Multi-Pass configurations.

Double Wall channels allow visual leak detection of heat exchangers.

The design of the double wall brazed plate heat exchanger prevents cross contamination of fluid streams if there is an internal leak within the unit. Two plates are joined together per heat-transfer plate couple, providing isolation and compartmentalization of fluids flowing through the heat exchanger.

Visual leak detection system.

Double Wall Brazed Plate heat exchangers provide a unique leakage pathway between plates that allows fluids to escape from the leaking plates to the outside environtment. Allowing early detection of the leaking condition for the double wall heat exchangers, permitting faster maintenance and lowring down-time.

Double Wall Brazed Plate heat exchangers prevent cross-contamination of fluids if a leak occurs in the plate walls. Double wall heat exchangers are ideal for compact applications requiring highest isolation of fluids such as potable water heating, food and beverage processing, and hospital applications.

We are represented through a network of authorized distributors. Contact our head office to find the distributor nearest you.

AIC is a group of companies that offers complete heat transfer solutions to the global market. Our expertise in this field stems from years of knowledge and working experience with diverse applications and industries around the world. AIC distinctive and versatile product designs, merged with advanced manufacturing technologies, have enabled us to continue our tradition of providing you with unique solutions to your most challenging needs.

© 2015 Advanced Industrial Components

Our success is based on the technical strengths and capabilitites of our people, the quality and diversity of our products, and our relentless pursuit to meet and exceed your expectations.